Product code: N/A

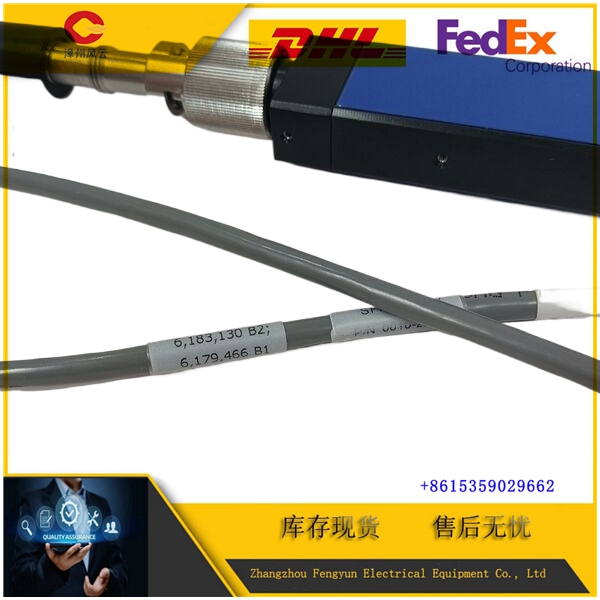

AMAT 0010-23716 | Precision mechanical component

¥99,999.00 Original price was: ¥99,999.00.¥3,587.00Current price is: ¥3,587.00.

Product Category: Module/Controller/Server/Motor/Touch Screen

Warranty: 12 months/365 days

Please contact me: 15359029662 Ms. Amy Sun

Chinese official website: www.dcsplcabb.com

Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

If you have any products that you cannot find, you can consult anytime.

Detailed content

Here is a detailed product datasheet for AMAT 0010-23716, featuring original English content with technical specifications, installation and maintenance tips, icons, and recommended similar models with hyperlinks:

AMAT 0010-23716 Product Datasheet

📦 Product Overview

The AMAT 0010-23716 is a precision-engineered component designed for use in advanced semiconductor manufacturing equipment. Manufactured by Applied Materials (AMAT), this part ensures reliable operation within complex wafer processing systems. Known for its robust construction and strict quality controls, the AMAT 0010-23716 plays a critical role in maintaining high throughput and process accuracy in semiconductor fabs. Its compatibility with multiple systems makes it a versatile choice for production line optimization.

📊 Key Technical Specifications

| Parameter | Specification | Icon |

|---|---|---|

| Model Number | 0010-23716 | 🏷️ |

| Manufacturer | Applied Materials (AMAT) | 🏭 |

| Type | Precision mechanical component | ⚙️ |

| Material | High-grade stainless steel and alloys | 🔩 |

| Dimensions | Approx. 150 mm x 75 mm x 30 mm | 📏 |

| Weight | Approx. 0.5 kg | ⚖️ |

| Operating Temperature Range | -10°C to 85°C | 🌡️ |

| Compatible Systems | Various AMAT wafer processing tools | 🔄 |

| Mounting Type | Bolt-on installation | 🔧 |

| Tolerance | Precision machining to ±0.01 mm | 🎯 |

🔧 Installation and Maintenance Instructions

- Installation:

- Ensure that the mounting surface is clean and free from debris before installing the component.

- Use the recommended bolts and torque settings to secure the part properly. Over-tightening may cause deformation; under-tightening may cause instability.

- Confirm alignment according to the equipment manual to maintain optimal operation.

- Maintenance:

- Inspect the component regularly for signs of wear, corrosion, or mechanical damage.

- Clean the part using lint-free cloths and approved solvents to avoid contamination.

- Avoid exposure to excessive moisture or corrosive chemicals that may degrade the material.

- Replace the part immediately if any significant damage or wear is detected to prevent process disruptions.

- Usage Tips:

- Always handle with care during installation and maintenance to avoid impacting precision surfaces.

- Document replacement and maintenance activities to keep a clear service history.

- Ensure compatibility with the latest equipment firmware and hardware updates.

📰 Industry News and Trends

In the rapidly evolving semiconductor industry, component reliability directly influences manufacturing yield and cost-efficiency. Applied Materials continues to innovate with precision components like the AMAT 0010-23716 to meet the demands of smaller process nodes and higher wafer throughput. The push toward automation and real-time equipment monitoring highlights the importance of durable, high-quality parts that integrate seamlessly into modern semiconductor fabs. Industry trends emphasize predictive maintenance and smart manufacturing, where components with stable performance and long lifespans are vital.

🌐 Additional Product Information and Links

🔎 Recommended Similar Models

| Model Number | Description | Link |

|---|---|---|

| AMAT 0010-23710 | Precision mechanical part for wafer handlers | View Product |

| AMAT 0010-23720 | High-tolerance component for deposition tools | View Product |

| AMAT 0010-23730 | Replacement module for AMAT etch systems | View Product |

| AMAT 0010-23740 | Structural part used in semiconductor cleaners | View Product |

| AMAT 0010-23750 | Precision machined part for lithography tools | View Product |

If you want, I can also help prepare a formatted PDF datasheet for your reference or client presentations. Just let me know!

_副本.jpg)