Product code: N/A

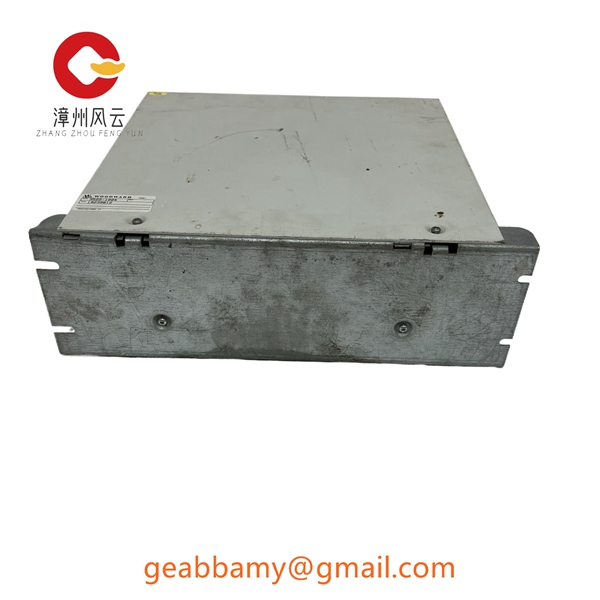

TRICONEX MP3101| Safety Controller Processor Module

¥99,999.00 Original price was: ¥99,999.00.¥2,295.00Current price is: ¥2,295.00.

Product Category: Module/Controller/Server/Motor/Touch Screen

Warranty: 12 months/365 days

Please contact me: 15359029662 Ms. Amy Sun

Chinese official website: www.dcsplcabb.com

Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

If you have any products that you cannot find, you can consult anytime.

Detailed content

Here is a detailed, original English datasheet for TRICONEX MP3101, including technical specs, installation & maintenance tips, icons, and recommended similar models with hyperlinks:

TRICONEX MP3101 Product Datasheet

📦 Product Overview

The TRICONEX MP3101 is a high-reliability processor module designed specifically for safety-critical industrial automation systems. It is part of the renowned Triconex family, well-known for its fault-tolerant architecture and robust performance in demanding environments such as oil & gas, power generation, and petrochemical industries. The MP3101 processor module delivers deterministic execution of control logic with real-time diagnostics, ensuring continuous system availability and maximum safety integrity.

![]()

📊 Key Technical Specifications

| Parameter | Specification | Icon |

|---|---|---|

| Model Number | MP3101 | 🏷️ |

| Module Type | Safety Controller Processor Module | ⚙️ |

| Processor | High-speed 32-bit CPU | 💻 |

| Memory | 2 MB non-volatile RAM | 💾 |

| Operating Voltage | 24 V DC ±10% | ⚡ |

| Power Consumption | Max 10 W | 🔋 |

| Communication | Triconex proprietary bus, Ethernet optional | 🌐 |

| Operating Temperature | -40°C to +70°C | 🌡️ |

| Mounting | DIN rail or rack mounting | 🛠️ |

| Dimensions | 200 mm x 40 mm x 120 mm | 📏 |

| Certification | SIL 3 certified | ✅ |

🔧 Installation and Maintenance Guidelines

- Installation:

- Install the MP3101 module into compatible Triconex chassis or racks, ensuring secure connection to backplane connectors.

- Confirm all cabling and communication links are correctly seated and labeled.

- Maintain clearance for ventilation and avoid exposure to excessive dust or moisture.

- Ground the system properly to prevent electrical noise or damage.

- Maintenance:

- Perform routine visual inspections to identify any physical damage or loose connectors.

- Use only manufacturer-approved firmware updates to maintain system integrity and security.

- Clean the module with a dry, lint-free cloth; avoid solvents or moisture.

- Verify processor diagnostics regularly through the system interface to detect faults or performance degradation.

- Ensure power supply voltage remains within specified limits to avoid unexpected shutdowns.

- Operational Tips:

- Document all installation and maintenance procedures to facilitate troubleshooting.

- Train maintenance personnel on safety protocols when handling critical safety modules.

- Schedule preventive maintenance during planned downtime to minimize operational impact.

📰 Industrial Insights

With industrial automation evolving rapidly, safety systems like those powered by the TRICONEX MP3101 are critical for safeguarding human life and protecting valuable assets. The module’s fault-tolerant architecture supports redundant processing and continuous self-checks, aligning with modern demands for reliability in harsh environments. As industries adopt Industry 4.0 practices, such controllers increasingly integrate with digital monitoring platforms, enhancing predictive maintenance and real-time diagnostics capabilities. This trend drives safer, more efficient plant operations worldwide.

🌐 Additional Product Information and Links

🔎 Recommended Similar Products

| Model | Description | Link |

|---|---|---|

| MP3102 | Enhanced processor module with faster CPU | View Product |

| MP3200 | Advanced Triconex processor with Ethernet | View Product |

| MP3500 | High-performance safety processor module | View Product |

| MP3100 | Standard Triconex processor module | View Product |

| MP3300 | Processor with integrated diagnostics | View Product |

If you need a formatted PDF datasheet or any further assistance, please feel free to ask!