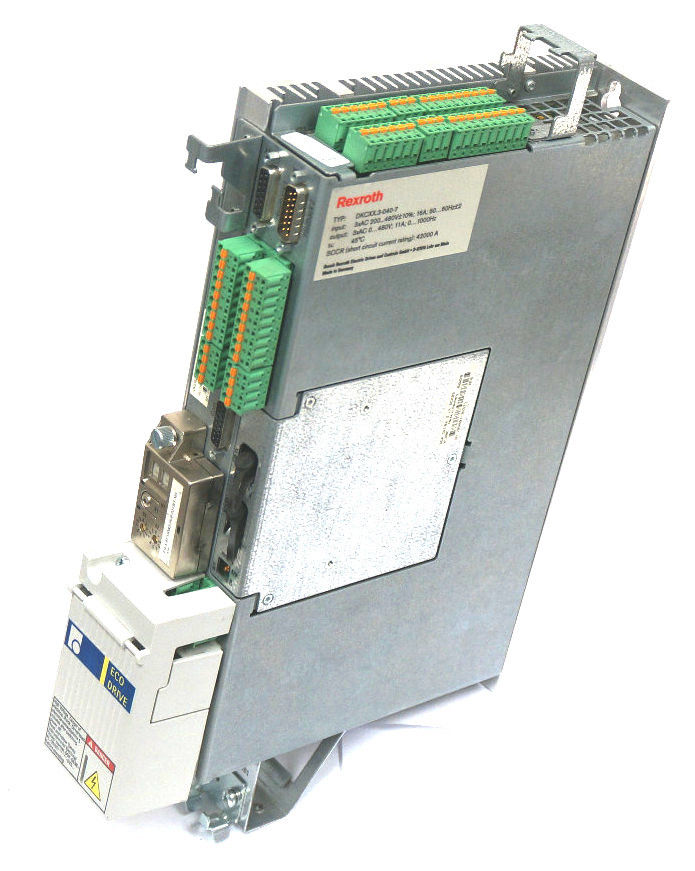

Rexroth Indramat DKC02.3-040-7-FW EcoDriver Servo Drive (Model: DKC02.3 R911279427)

The Rexroth Indramat DKC02.3-040-7-FW EcoDriver Servo Drive is a high-performance, state-of-the-art servo drive designed for demanding industrial applications, particularly in automation, robotics, packaging, and material handling systems. As part of the Indramat EcoDrive series, this drive combines precision, efficiency, and high power density with compact design, offering excellent control over servo motors for high-performance motion control applications.

This particular model (DKC02.3-040-7-FW) is engineered for flexibility, ease of integration, and energy-efficient operation, making it an ideal solution for a wide variety of industrial motion control systems.

Key Features:

- High Power Density: The DKC02.3 EcoDrive offers compact power handling, reducing space requirements while maintaining exceptional performance levels. This is especially beneficial for systems where space constraints are an issue.

- Advanced Motion Control: Provides precise control of servo motors with fast response times, enabling high-precision motion in automated systems.

- Integrated Safety Functions: Equipped with advanced safety features such as STO (Safe Torque Off), SLS (Safely Limited Speed), and other protective measures to ensure safe operation in critical industrial environments.

- High-Efficiency Design: The EcoDrive technology reduces energy consumption, making the system cost-effective and environmentally friendly.

- Flexible Communication Interfaces: Supports multiple communication protocols, including SERCOS III, EtherCAT, and PROFIBUS for easy integration with other industrial automation systems and controllers.

- Diagnostics and Monitoring: Offers advanced diagnostics and monitoring capabilities, including real-time fault detection, motor condition monitoring, and performance analysis. This enables proactive maintenance and troubleshooting.

- Regenerative Energy Feedback: Capable of feeding back regenerative energy into the power supply, making it highly energy-efficient.

- Compact and Robust: Designed to withstand the rigors of industrial environments, the DKC02.3 is rugged, reliable, and capable of operating in extreme conditions.

Technical Specifications:

- Model: DKC02.3-040-7-FW

- Nominal Output Power: 4.0 kW (kilowatts)

- Input Voltage: 400-480V AC (Three-phase)

- Power Supply: 3-phase AC

- Control Types Supported: Velocity control, Position control, Torque control

- Cooling Type: Air-cooled (natural convection)

- Communication Interface:

- SERCOS III

- EtherCAT

- PROFIBUS

- Input/Output Signals: Analog and digital I/O for motor feedback and control

- Environment Operating Temperature: 0°C to 40°C (32°F to 104°F)

- Weight: Approx. 6.5 kg

- Dimensions: 320 mm x 160 mm x 180 mm (H x W x D)

- Enclosure: IP20 rated (protection against solid objects over 12mm in diameter)

- Safety: Compliant with EN 61800-5-2 (Functional Safety), CE marked for safety compliance

- Protection Features:

- Overcurrent protection

- Overvoltage protection

- Overtemperature protection

- Short-circuit protection

- Earth fault protection

Applications:

The Rexroth Indramat DKC02.3 EcoDriver is used in a wide variety of motion control applications, including:

- Industrial Automation: Integration into automated production lines, conveyor systems, and packaging machines where precision and reliability are critical.

- Robotics: Servo control for robotic arms, pick-and-place systems, and other precision robotics applications.

- Material Handling: Controlling motors in material handling systems such as cranes, lifts, and automated storage/retrieval systems.

- CNC Machines: Control of motors in CNC machine tools for precise motion and accuracy in cutting, milling, and drilling.

- Textile and Printing Industries: Used for motion control in textile machines, printing presses, and other continuous manufacturing processes.

- Packaging: Ensuring high-speed and precise control of motors in packaging equipment, including filling, capping, and labeling machines.

Installation & Maintenance Instructions:

- Installation:

- Mounting: The DKC02.3 servo drive should be mounted in a well-ventilated area to ensure effective cooling. It can be installed on a DIN rail or in an enclosure, keeping sufficient space for airflow around the device.

- Wiring: Properly wire the drive to the motor and power supply, ensuring that connections are secure and that the device is grounded appropriately. Ensure that all communication cables (for protocols like SERCOS III or EtherCAT) are also connected properly to the control system.

- System Integration: Configure the drive to communicate with the industrial controller (PLC, SCADA, or similar) using the appropriate communication protocol. Check the settings for torque, velocity, and position control modes, based on your application needs.

- Power-up: Once wired, power up the system and follow the manufacturer’s guidelines to perform initial setup, including motor tuning and testing.

- Maintenance:

- Routine Inspections: Regularly check the unit for signs of wear or overheating, particularly around connectors and cooling vents. Ensure that the cooling fins and vents are free from dust or obstructions to prevent overheating.

- Diagnostics: Use the drive’s diagnostic functions to monitor system performance. Perform regular fault detection and motor condition analysis to ensure optimal operation.

- Firmware Updates: Ensure that the drive is operating with the latest firmware. Update firmware as recommended by the manufacturer to improve performance or security.

- Connection Checks: Verify that all electrical connections, including communication interfaces, are secure and show no signs of wear, corrosion, or loose contacts.

- Motor and Drive Alignment: Check the alignment and balancing of the motor to ensure that it operates efficiently and that the drive is not subjected to excess mechanical stress.

Product Recommendations:

If you’re looking for similar or complementary servo drives, here are a few alternatives that offer similar performance for industrial applications:

| Product | Description | Link |

|---|---|---|

| Bosch Rexroth Indramat DKC01.3 | A high-performance servo drive suitable for both small and medium-sized applications. | Bosch Rexroth Indramat DKC01.3 |

| Siemens Sinamics S120 | A modular drive system offering high performance for motion control applications. | Siemens Sinamics S120 |

| Yaskawa Sigma-7 | A next-generation servo drive offering high-speed control and precision for demanding applications. | Yaskawa Sigma-7 |

Advantages of the Rexroth DKC02.3 EcoDriver:

- Energy Efficiency: The EcoDrive technology minimizes energy usage, making it a cost-effective solution in long-term operations.

- Precision Control: Offers excellent motor control in both position and speed applications, with precise response times.

- Advanced Diagnostics: Continuous monitoring of the drive and motor performance allows for predictive maintenance and reduced downtime.

- Compact Design: The drive’s small footprint allows for integration in tight spaces, without compromising on power or performance.

- Safety Compliance: Built-in safety functions ensure that the system operates within safe limits, protecting both the drive and the overall machinery.

Conclusion:

The Rexroth Indramat DKC02.3-040-7-FW EcoDriver Servo Drive offers a powerful, efficient, and reliable solution for a variety of industrial motion control applications. Its compact design, advanced safety features, and energy-efficient operation make it an ideal choice for applications requiring high precision, reliability, and long-term operational savings. Whether in robotics, industrial automation, or material handling, the DKC02.3 provides the performance and flexibility needed to meet modern industrial demands.