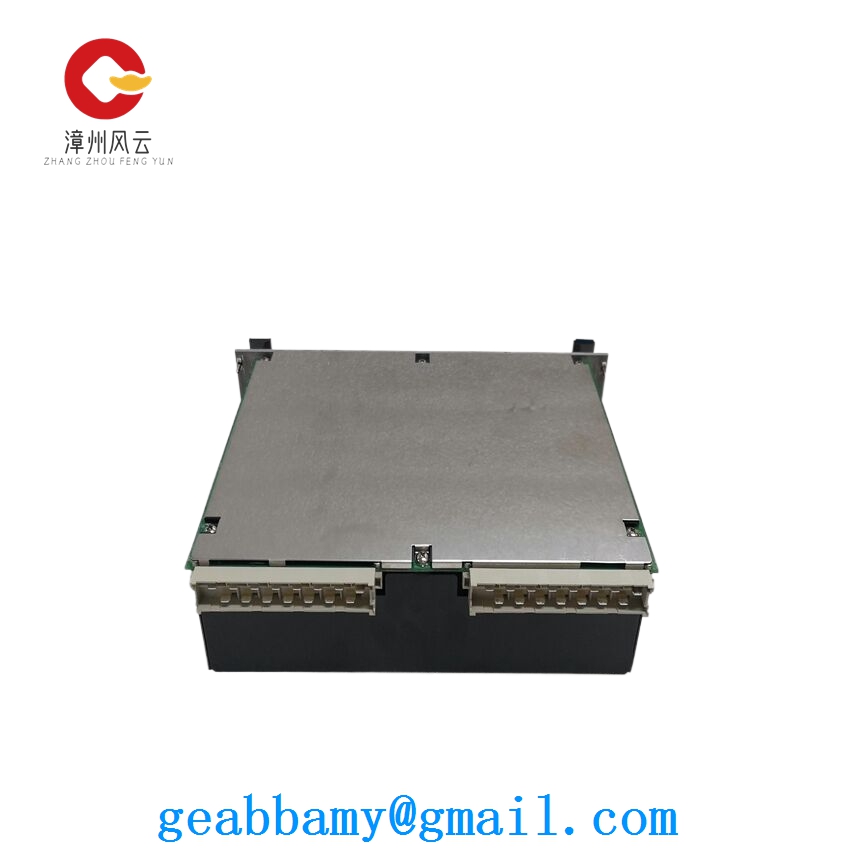

Technical Parameters of ABB PM902F Process Station for AC900F Controller

1. General Overview

The ABB PM902F Process Station is a key component within the ABB AC900F distributed control system (DCS). It is designed to handle a wide range of process control tasks in industrial environments, offering high reliability, performance, and flexibility to meet the demanding requirements of modern industrial automation.

2. Hardware Specifications

2.1 Processor

- Type: High – performance 32 – bit or 64 – bit processor (specific details may vary depending on the exact revision). It is optimized for real – time process control applications, enabling fast execution of control algorithms and data processing.

- Clock Speed: Typically operates at a clock speed that ensures rapid response to process changes, with a base frequency that can reach several hundred megahertz, providing sufficient computational power for complex control strategies.

2.2 Memory

- RAM: Equipped with a generous amount of RAM, usually ranging from several megabytes to gigabytes, depending on the configuration. This allows for the storage of large amounts of process data, control programs, and historical information, facilitating smooth operation and analysis.

- Flash Memory: Features built – in flash memory for non – volatile storage of the operating system, control applications, and configuration data. This ensures that the process station can retain its settings and programs even in the event of a power failure.

2.3 I/O Interfaces

- Digital Inputs: Supports a number of digital input channels, which can be used to monitor binary states such as switch positions, limit switches, and digital sensor signals. The input voltage range and isolation characteristics are designed to meet industrial standards, typically providing high – voltage isolation to protect the internal circuitry from external electrical noise and transients.

- Digital Outputs: Offers a set of digital output channels for controlling binary devices such as valves, relays, and solenoids. The output channels can source or sink sufficient current to drive various types of loads, and they also include protection mechanisms against over – current and short – circuit conditions.

- Analog Inputs: Includes analog input channels that can accept a wide range of analog signals, such as 4 – 20 mA, 0 – 10 V, etc. These channels are equipped with high – precision analog – to – digital converters (ADCs) to accurately convert the analog signals into digital values for processing by the control system.

- Analog Outputs: Provides analog output channels for generating analog control signals to drive analog devices like variable – speed drives and control valves. The output channels use high – quality digital – to – analog converters (DACs) to ensure accurate and stable signal generation.

2.4 Communication Interfaces

- Ethernet Port: Equipped with one or more Ethernet ports, typically supporting 10/100/1000 Mbps data transfer rates. These ports enable the process station to communicate with other devices in the AC900F DCS, such as the operator stations, engineering stations, and other process stations, as well as with external systems via standard Ethernet protocols like TCP/IP.

- Serial Ports: May include serial communication ports (e.g., RS – 232, RS – 485) for connecting to legacy devices or for special communication requirements. These ports provide flexibility in integrating with a wide variety of industrial equipment.

2.5 Power Supply

- Input Voltage Range: Accepts a wide input voltage range, typically from 85 – 264 V AC or 110 – 300 V DC, making it suitable for use in different power supply environments around the world.

- Power Consumption: Has relatively low power consumption, which helps to reduce operating costs and environmental impact. The exact power consumption depends on the configuration and load of the I/O modules.

3. Software Compatibility

- Operating System: Runs on a real – time operating system (RTOS) specifically designed for industrial control applications. This RTOS provides deterministic behavior, ensuring that control tasks are executed within strict time constraints, which is crucial for maintaining process stability and safety.

- Control Software: Fully compatible with the ABB AC900F control software suite, which includes programming tools for developing control strategies, human – machine interface (HMI) software for operator interaction, and configuration tools for setting up the process station and I/O modules.

4. Environmental Specifications

- Operating Temperature: Can operate in a wide temperature range, typically from – 20°C to + 60°C (or – 4°F to + 140°F), allowing it to be installed in various industrial environments, including those with extreme temperature conditions.

- Storage Temperature: Has a storage temperature range that is even wider, ensuring that the process station can be stored safely without damage when not in use.

- Humidity: Designed to operate in environments with a relative humidity range of 5% to 95% (non – condensing), making it suitable for use in humid industrial settings.

- Vibration and Shock Resistance: Meets industrial standards for vibration and shock resistance, ensuring reliable operation even in environments with mechanical vibrations or occasional shocks, such as in manufacturing plants or near heavy machinery.

5. Reliability and Redundancy

- Mean Time Between Failures (MTBF): Has a high MTBF, indicating a long – term reliable operation. This is achieved through the use of high – quality components, robust design, and thorough testing during the manufacturing process.

- Redundancy Options: Supports redundancy configurations, such as redundant processors, power supplies, and communication links. Redundancy enhances system availability by providing backup components that can take over in the event of a failure, minimizing process downtime.

In summary, the ABB PM902F Process Station for the AC900F controller is a highly capable and reliable industrial process control device that combines advanced hardware features, software compatibility, and environmental robustness to meet the diverse needs of modern industrial automation applications.