BACHMANN AIC212 Control Module

The BACHMANN AIC212 Control Module is a versatile and high-performance module designed for control and automation systems, primarily used in industrial applications such as power generation, factory automation, and process control. The AIC212 is part of Bachmann’s M1 series, offering exceptional flexibility and robust functionality, making it an ideal choice for machine control, system monitoring, and process regulation. This control module supports a wide variety of control tasks and can be easily integrated into complex automation systems.

The AIC212 is designed to provide a comprehensive solution for data acquisition, signal processing, and system interfacing, all while maintaining high standards of precision, reliability, and safety. It is particularly useful in systems where high-speed processing and accurate control are critical.

Key Features:

- Versatile Control Functions: Supports a wide range of control functions, such as process control, machine monitoring, and data acquisition, enabling it to fit seamlessly into diverse industrial automation environments.

- Modular Design: Designed to be part of Bachmann’s M1 modular system, allowing easy integration with other M1 modules to expand functionality and meet specific application requirements.

- High-Speed Processing: Capable of handling high-speed signals and real-time data processing, ensuring precise control and reliable system operation.

- I/O Expansion: Features a variety of digital and analog I/O options, making it adaptable for different control applications. It can interface with a wide range of sensors, actuators, and other devices.

- Communication Protocols: Supports communication protocols like Ethernet, Modbus, CANopen, and Profibus (depending on configuration), allowing easy integration with other systems, controllers, and field devices.

- Diagnostics and Monitoring: Includes built-in diagnostics for monitoring the health and status of the system, allowing for easy troubleshooting and maintenance.

- Real-time Operating System: The control module operates on a real-time operating system, ensuring high-accuracy and low-latency performance for time-sensitive applications.

- Flexible Configuration: Supports multiple configuration options via software tools, allowing users to tailor the control module to their specific requirements.

- Compact and Robust Design: Built for demanding environments, the module features a compact design that can fit into limited spaces while offering robust protection against environmental factors.

Technical Specifications:

- Model Number: AIC212

- Type: Control module for data acquisition and process control

- Communication Protocols:

- Ethernet for high-speed communication and integration with networks

- Modbus and Profibus for industrial automation and field device interfacing

- CANopen for compatibility with distributed control systems

- Power Supply: Typically 24 VDC, with tolerance for a wide range of input voltages

- Operating Temperature: -20°C to +60°C (-4°F to +140°F)

- Storage Temperature: -40°C to +85°C (-40°F to +185°F)

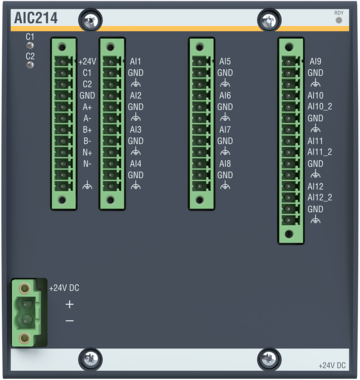

- I/O Capabilities: Digital I/O and analog I/O, configurable for a variety of industrial sensors and actuators

- Mounting: Designed for DIN rail mounting, which is a common method for industrial control systems

- Dimensions: 150 mm x 110 mm x 35 mm (approx.)

- Weight: 0.5 kg (approx.)

- Protection Class: IP20 (indoor use with protection against dust ingress)

- Bus Systems: Support for CAN and Ethernet-based bus systems

- Status Indicators: Includes LED indicators for power, communication status, and I/O status, simplifying diagnostics and monitoring

- Real-Time Operation: Includes real-time processing capabilities, suitable for critical industrial applications that require precise timing and fast data handling

Protection Features:

- Overvoltage Protection: Designed to protect the module against voltage surges and fluctuations, ensuring long-term reliability and avoiding potential damage.

- Reverse Polarity Protection: Prevents damage from incorrect wiring during installation or maintenance.

- Short Circuit Protection: Ensures that the module is protected in case of short circuits in connected circuits or wiring.

- Temperature Monitoring: Features built-in thermal protection to prevent overheating and ensure reliable operation under high ambient temperatures.

- Overcurrent Protection: Built-in protection to prevent excessive current from damaging the module or connected devices.

Installation & Maintenance Instructions:

- Installation:

- Mount the BACHMANN AIC212 Control Module on a DIN rail in a clean, dry, and ventilated control panel. Ensure the mounting location has sufficient space for wiring and other components.

- Connect the 24 VDC power supply to the input terminals. Ensure correct polarity and provide a stable power source to ensure reliable operation.

- Connect the digital and analog I/O terminals to the corresponding field devices (e.g., sensors, actuators) following the specifications outlined in the user manual.

- For network communication, connect the module’s Ethernet port or CANopen/Profibus terminals to the corresponding bus or network system for integration with the larger automation system.

- Use the software configuration tool (provided by Bachmann) to set the necessary parameters for communication, I/O assignments, and control logic.

- Configuration:

- The module can be easily configured using Bachmann’s M1 software tools, which allow users to set up communication parameters, I/O assignments, and control logic based on the specific requirements of the application.

- The software offers an intuitive interface to configure the module without needing complex programming knowledge, although advanced users can write custom control algorithms.

- Set up the communication protocols to match the existing industrial network (Ethernet, Modbus, CANopen, etc.).

- Once configured, download the settings to the module and verify the system is functioning as expected using the module’s diagnostics and status indicators.

- Maintenance:

- Regularly check the power supply and wiring connections to ensure they are secure and free from damage, corrosion, or wear.

- Inspect the module’s cooling (if necessary) to ensure that the device operates within the specified temperature range.

- Monitor the status LEDs to ensure the system is functioning correctly and that no faults or warnings are present.

- If applicable, perform periodic software updates to improve system performance, compatibility, and security.

- Use the diagnostic tools provided by the configuration software to perform system health checks and troubleshoot issues quickly.

- Calibrate the I/O devices connected to the module as required to maintain measurement accuracy over time.

Product Recommendations:

For additional control and automation solutions, consider the following products:

| Product | Description | Link |

|---|---|---|

| Bachmann M1 Control System | Comprehensive modular control system with integration for automation and process control. | Bachmann M1 |

| Siemens S7-1200 PLC | Modular PLC with versatile I/O and communication options for industrial automation. | Siemens S7-1200 |

| Schneider Electric Modicon M241 PLC | A flexible PLC solution for advanced process control and automation. | Schneider M241 |

Advantages of the BACHMANN AIC212 Control Module:

- Modular Design: Easily integrates into the Bachmann M1 system, allowing scalability and flexibility in your automation setup.

- Real-Time Performance: Offers fast processing and control for time-sensitive applications, improving operational efficiency.

- Communication Flexibility: Supports various industrial communication protocols, including Ethernet, Modbus, and CANopen, ensuring compatibility with a wide range of devices and systems.

- Built-in Diagnostics: Features diagnostic tools to help with system maintenance and troubleshooting, reducing downtime.

- Compact and Robust: Its compact design allows for installation in tight spaces while maintaining durability and reliability in harsh industrial environments.

Conclusion:

The BACHMANN AIC212 Control Module is an excellent solution for a wide range of industrial control applications. Its versatility, real-time performance, and support for multiple communication protocols make it suitable for various automation tasks, from machine control to data acquisition and process monitoring. With easy integration into Bachmann’s M1 system, along with its robust protection features and user-friendly configuration, the AIC212 ensures reliable, high-performance operation in demanding industrial environments.