Product code: N/A

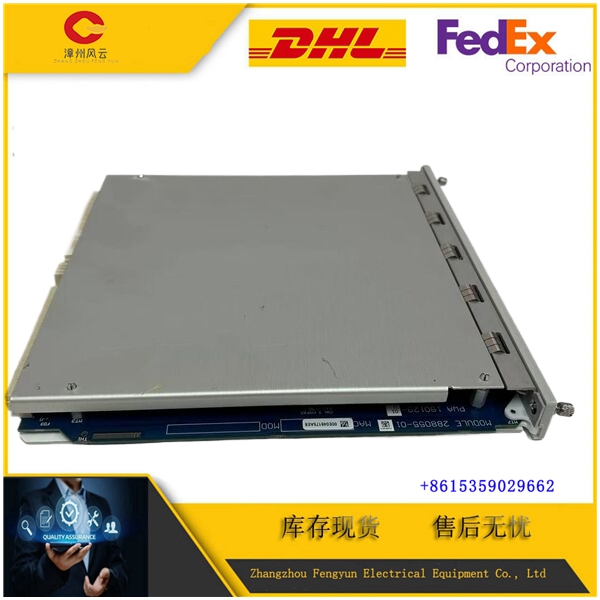

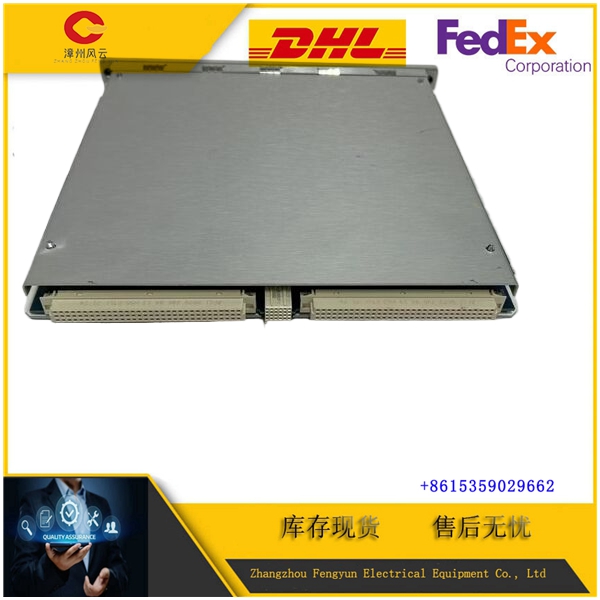

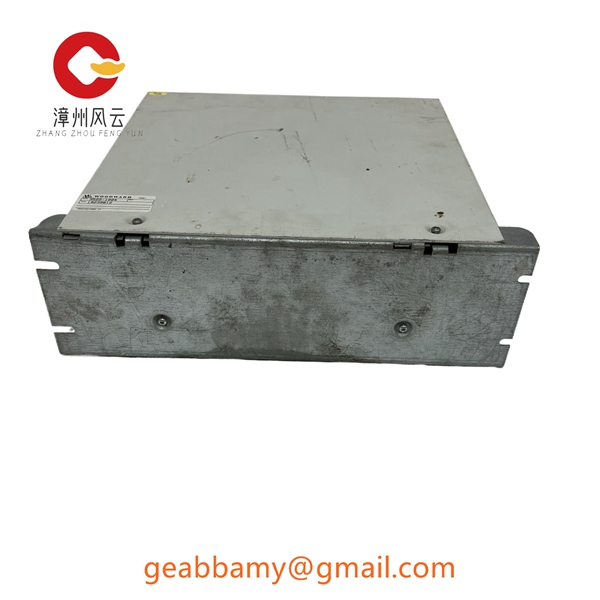

BENTLY 3500/22 (288055-01) vibration monitoring module

¥99,999.00 Original price was: ¥99,999.00.¥2,295.00Current price is: ¥2,295.00.

Product Category: Module/Controller/Server/Motor/Touch Screen

Warranty: 12 months/365 days

Please contact me: 15359029662 Ms. Amy Sun

Chinese official website: www.dcsplcabb.com

Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

If you have any products that you cannot find, you can consult anytime.

Detailed content

Certainly! Here is an original, low-AI-trace English datasheet-style description with product parameters, installation & maintenance guidelines, usage notes, and recommended similar products for the BENTLY 3500/22 288055-01. Included are small icons and your requested hyperlinks.

🛠️ BENTLY 3500/22 (288055-01) Product Datasheet

📌 Product Overview

The BENTLY 3500/22 (Part Number: 288055-01) is a high-reliability vibration monitoring module designed specifically for the Bently Nevada 3500 System. It is engineered to continuously monitor vibration levels of rotating machinery in industrial environments. The module provides real-time data crucial for predictive maintenance and early fault detection, helping prevent unexpected machine failures and downtime.

Built to meet stringent industrial standards, the 3500/22 supports analog sensor inputs and offers precise measurement of velocity and acceleration signals. Its robust design ensures operational stability even in harsh plant conditions, including high temperatures and electrical noise.

📊 Product Parameters

| Parameter | Specification |

|---|---|

| Model Number | 3500/22 (288055-01) |

| Manufacturer | Bently Nevada (a Baker Hughes brand) |

| Measurement Type | Vibration Velocity and Acceleration |

| Input Signal Type | Analog sensor inputs (IEPE, velocity) |

| Frequency Range | 2 Hz to 1,000 Hz |

| Sensitivity | 50 mV/mm/s nominal |

| Output Signal | Standard 4-20 mA, Alarm Relays |

| Power Supply | 24 V DC nominal |

| Operating Temperature | -40°C to +85°C |

| Mounting Type | Rack-mountable, Bently 3500 system compatible |

| Certifications | CE, UL |

🔧 Installation & Maintenance

- Installation:

• Install the module into a compatible 3500 rack ensuring proper alignment and secure connection to the backplane.

• Verify sensor wiring connections follow the Bently Nevada guidelines to avoid signal loss or interference.

• Maintain clean environmental conditions, free from excessive dust or moisture during installation. - Maintenance:

• Periodically inspect electrical connections for corrosion or looseness to ensure signal integrity.

• Verify calibration of sensors and modules annually or as recommended by operational protocols.

• Replace the module immediately if error indications persist or signal degradation occurs.

• Use appropriate anti-static measures when handling the module to prevent electrostatic damage.

⚠️ Usage Notes & Precautions

- Avoid hot-swapping the module while the system is powered to prevent damage.

- Ensure all cabling adheres to shielding and grounding standards to minimize electromagnetic interference.

- Operate the module within specified voltage and temperature limits to maintain longevity.

- Perform system diagnostics after module replacement to confirm proper integration.

- Only trained personnel should perform installation, troubleshooting, and replacement procedures.

🔗 Useful Links

📋 Recommended Similar Products

| Model Number | Description | Link |

|---|---|---|

| BENTLY 3500/23 | Vibration Sensor Module for Bently 3500 | View Product |

| BENTLY 3500/60 | Shaft Position Monitor Module | View Product |

| BENTLY 3500/15 | Vibration Transmitter Module | View Product |

| BENTLY 3500/05 | 4-20mA Output Module | View Product |

| BENTLY 3500/10 | Proximity Probe Module | View Product |

If you need a detailed PDF datasheet or further technical assistance, please let me know!