Product code: N/A

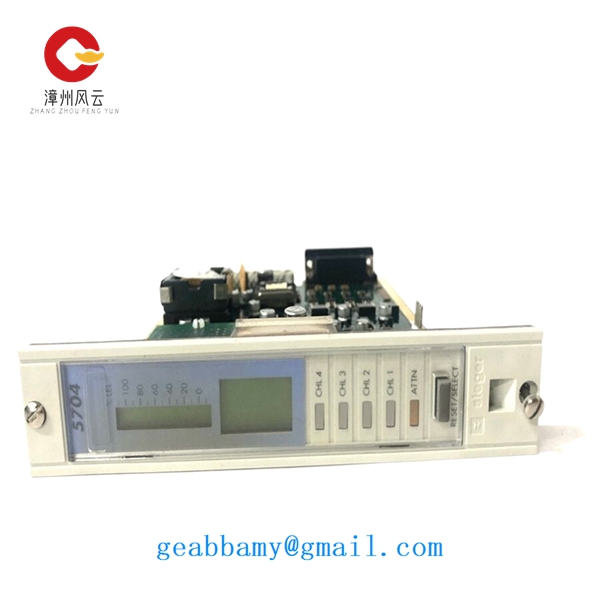

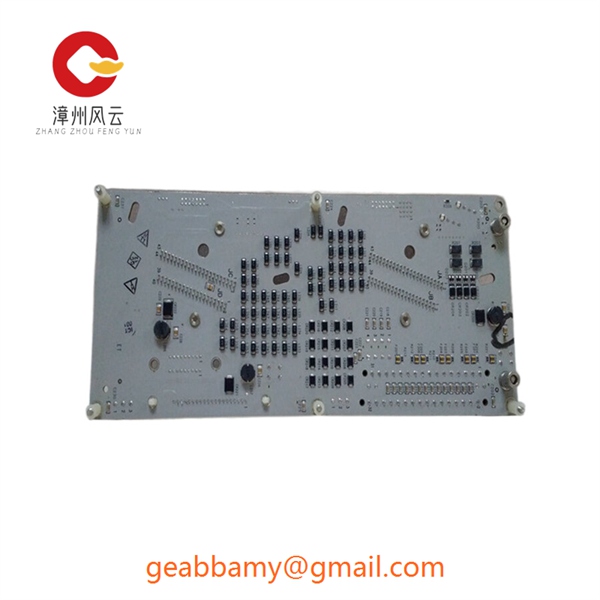

HONEYWELL 05704-A-0145 Four channel control module

Brand: HONEYWELL SIEGER

Models: 05704-A-0145

Product status: New/used

Shipping place: Zhangzhou, China

Delivery method :fedex /DHL

Delivery time :2-3 working days

Please contact Amy for quotation, thank you!

📩Email: geabbamy@gmail.com

💬Whatsapp: +86 15359029662

Detailed content

HONEYWELL 05704-A-0145 Four channel control module

HONEYWELL 05704-A-0145 Module Manual (Summary Version)

1、 Product Overview

model: HONEYWELL 05704-A-0145

Type: Four channel control module

Usage: Industrial automation control, multi parameter monitoring and control, distributed control system (DCS)

characteristic:

Four channel independent control: supports simultaneous processing of signals from four channels, suitable for multi device collaborative control.

High precision control: achieving precise position, speed, and process control.

Multiple communication interfaces: Supports Ethernet, serial communication, etc., making it easy to integrate with other devices.

Programmable: Supports programming languages such as ladder diagrams and structured text, allowing users to customize control logic according to their needs.

Security features: Equipped with user authentication, data encryption and other security mechanisms to ensure stable system operation.

2、 Technical parameters

Project parameters

Number of channels: 4 independent control channels

Input type: analog signal (voltage/current), digital signal

Output type analog/digital signal, supporting PWM control

Communication interface Ethernet RS-232/422/485

Programming Language Ladder Logic, Structured Text (ST)

Power requirement 24V DC

Working temperature -20 ° C to+70 ° C

Protection level IP20 (to be used in conjunction with protective casing)

3、 Functional characteristics

Multi channel independent control

Each channel can independently configure input/output signals and support monitoring of parameters such as temperature, pressure, and flow rate.

Example: Channel 1 controls the temperature sensor, channel 2 controls the pressure sensor, and channels 3 and 4 are used for actuator control.

Real time monitoring and feedback

Support real-time data collection and feedback to ensure system response speed.

Real time data can be viewed through HMI (Human Machine Interface) or SCADA system.

Communication and Integration

Supports industrial protocols such as Modbus and Profibus, making it easy to integrate with systems such as PLC and DCS.

Example: Communicate with the upper computer through Ethernet interface to achieve remote monitoring and control.

Safety and Diagnosis

Built in fault diagnosis function, capable of detecting channel faults, communication interruptions, and other issues.

Support alarm output, triggering an alarm when parameters exceed the set range.

Product related pictures: